Applications of Curved Glass in Interior Design

Understanding Curved Glass: Definition and Applications

Curved glass, sometimes called bent glass, gets made when regular glass goes through heating and molding processes to create those distinctive curves we see instead of just plain flat surfaces. What happens during this process gives curved glass some pretty cool characteristics like being stronger than standard glass and looking much better too. When compared to ordinary flat glass, curved versions offer customization options for both looks and function, making them really adaptable for different purposes. We actually see this adaptability all over the place these days in everything from modern architecture to automotive designs across many sectors of industry.

We see curved glass everywhere these days across all sorts of industries from buildings to cars and even our gadgets. Architects love using it on building exteriors because it gives structures that really stand out visually while still looking super modern. Inside spaces too, designers incorporate curved glass panels into things like fancy staircases and room dividers that serve multiple purposes at once. Car manufacturers definitely get creative with this material as well, especially when making windshields and back windows where the shape actually helps improve how air flows around the vehicle and keeps drivers safer during accidents. And let's not forget about phones and smartwatches either! The screens on many devices now feature this curved glass design which protects them better from drops and just looks really cool with those rounded edges. All these varied uses show why curved glass has become such an important part of so many different fields.

Types of Curved Glass and Their Characteristics

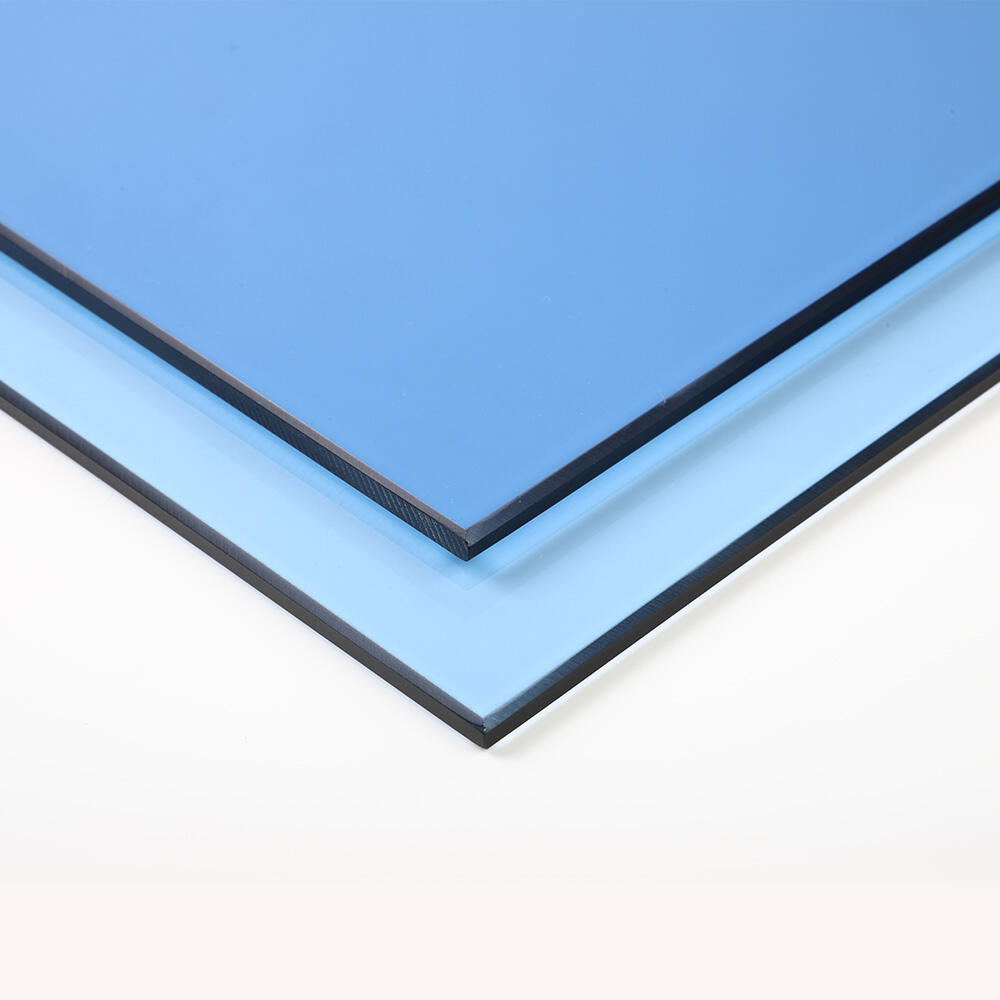

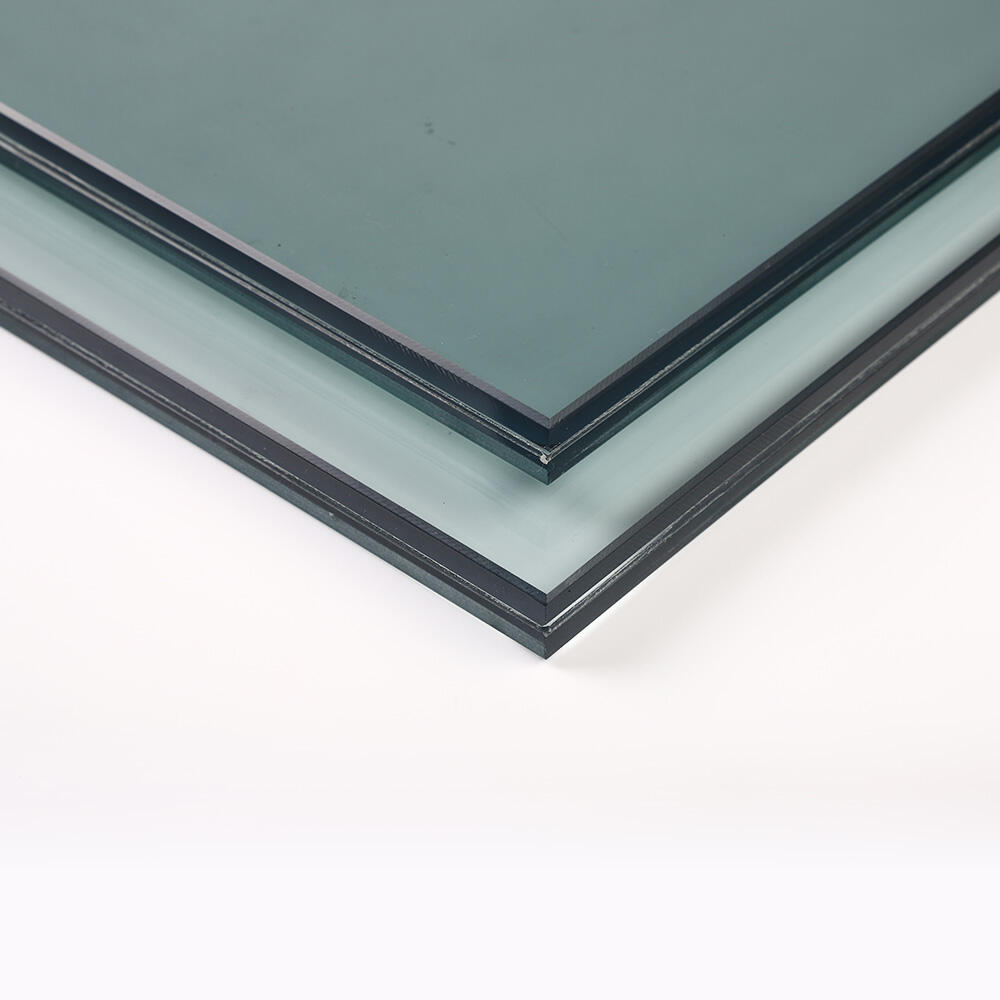

Curved glass comes in various forms, each with distinct properties for specific purposes. Take laminated curved glass for instance. When shattered, the plastic layer inside keeps everything intact, which is why car manufacturers rely on it so much for windshields. Then there's tempered curved glass. This stuff goes through intense heating processes during manufacturing, resulting in something roughly five times tougher than standard glass. That makes it perfect for tough spots like building facades or office dividers where durability matters most. Lastly we have what some folks call bent glass or annealed curved glass. While not as strong as tempered varieties, this type really shines when looks matter more than structural integrity. Interior designers love using it for things like ornamental panels or artistic installations where safety requirements aren't quite so strict.

Tempered curved glass really shines when it comes to strength and how long it lasts. Research indicates this kind of glass takes a lot more punishment than regular or laminated options. Take car windshields for example they don't break into those nasty little shards that cut people. That makes all the difference in terms of safety. Laminated glass has something going for it too though. There's this plastic layer sandwiched between the glass panels so even if it cracks, everything stays together instead of flying everywhere. Annealed curved glass isn't as tough obviously, but what it lacks in toughness it makes up for in looks and versatility for designers. Want to know which one works best? Look at what matters most for the project at hand security concerns, structural requirements, or just wanting something that looks good.

The Manufacturing Process of Curved Glass

Making curved glass starts with placing flat sheets onto specially crafted metal molds shaped exactly how we want them to curve. These sheets then go into industrial ovens where they get heated up until they become soft enough to work with. Getting the temperatures just right during this heating phase is absolutely critical because too hot and the glass might crack, while too cold means it won't bend properly. When the glass reaches that right consistency, it's time for shaping. Back in the old days, people relied mostly on gravity to let the glass slowly sag into place over the mold. Today though, most manufacturers use presses or other mechanical systems to force the glass against the mold surface. After shaping comes what's called annealing – basically letting the glass cool down very gradually inside another chamber. This slow cooling prevents internal stresses from building up, which could otherwise cause the finished product to warp or break later on when installed somewhere like a car windshield or architectural feature.

The way we make curved glass has gotten a lot better thanks to new tech stuff coming out all the time. These days, automated bending machines can shape glass with incredible accuracy, something that used to be nearly impossible when workers did everything by hand. Back then, mistakes happened all the time because human error was inevitable. What's really changed things though are the improvements in quality checks throughout the factory floor. With fancy monitoring systems watching every step of the process, manufacturers catch flaws much earlier than before. This means fewer rejects and better overall product quality. For companies producing curved glass, these upgrades mean stronger final products while saving money on waste and rework costs. Most people working in the industry believe there will be even more breakthroughs soon, which should open up totally new markets for curved glass applications beyond what we see today.

Cost Implications of Curved Glass Installations

Several things impact how much curved glass installations will set someone back. Bigger panels naturally cost more since they take extra materials and consume more energy during manufacturing. Then there's the matter of glass types. Annealed glass tends to be cheaper but weaker, while tempered and laminated versions command premium prices thanks to their enhanced durability and safety features. When customers want something really special though, that's when costs really start climbing. Custom curves that follow exact specifications or incorporate unusual design elements typically require custom molds and skilled artisans who know exactly what they're doing. These specialty projects can easily double or even triple the base price depending on just how complicated the requirements turn out to be.

Curved glass generally costs more than regular flat glass when we look at prices side by side. The reason behind this extra expense lies in how it gets made. Manufacturers need special equipment for heating, shaping, and cooling the glass during production. Some industry reports suggest that curved glass might end up costing anywhere from 15 to 30 percent more than standard options. Still, many architects and designers find these added costs worth it because curved glass brings something different to buildings. It creates interesting shapes and allows for creative designs that just aren't possible with flat panels. Plus, the way light interacts with curved surfaces often produces stunning visual effects that make structures stand out in urban environments.

Innovative Products Featuring Curved Glass

New tech has really pushed forward how we use curved glass across different products, resulting in some pretty cool engineering feats and better quality materials than ever before. Take Baloney Glass Fences as an example they showcase what's possible when good design meets solid construction. These fences combine strong materials with smart engineering so they last longer without breaking down. What makes them stand out is how well they fit into whatever setting they're placed in, whether it's a modern cityscape or something more traditional. Despite their sleek appearance, they hold up against weather and wear much better than most people would expect from such elegant looking structures.

When it comes to security for curved glass products, manufacturers are now using stronger materials and designing panels that can withstand riots. Take CdTe panels as an example these Cadmium Telluride panels do more than just convert sunlight efficiently. They actually hold up well during disturbances and stand up against harsh weather conditions too. That's why many businesses looking to save on energy costs while keeping their premises secure are turning to these types of panels. The combination of good performance and solid protection makes them particularly attractive for commercial buildings where both power savings and safety matter.

Baloney Glass Fences stand as a testament to industry standards in reliability and performance. These products blend functionality with aesthetics, offering not just security but also a modern, sophisticated appeal suitable for a wide range of applications from residential to commercial zones.

Benefits of Using Curved Glass in Contemporary Interiors

Curved glass really stands out in today's interior design scene, giving spaces that special something that feels both modern and sophisticated. What makes this material so appealing is how it can create those smooth, flowing lines without any visible seams. Architects love using it as a focal point in everything from luxury apartments to office buildings across the country. We're seeing more curved glass these days because it fits right into the prevailing style trends that favor natural curves over sharp angles. Plus, beyond just looking good, these installations actually work better functionally too since they allow for more creative lighting solutions and open sightlines throughout a room.

Curved glass does more than look good it actually offers some pretty practical advantages too. The way it fits into spaces makes all the difference when dealing with rounded walls or corners, basically letting architects make better use of every square inch. When it comes to lighting, curved glass spreads daylight around much better than regular flat panels. This means rooms feel brighter during the day without needing so many lights turned on at night, which obviously saves money on electricity bills. Architects are starting to catch onto this stuff, especially as green building standards become more important in today's construction projects.

Future Trends in Curved Glass Applications

Curved glass applications are going through some pretty major changes thanks to new tech like 3D printing. What we're seeing now allows for much more complicated shapes and designs that simply weren't possible before. With 3D printing technology, architects aren't stuck with the old constraints anymore when it comes to how curved their glass needs to be, what sizes they can work with, or the geometric possibilities available. This means buildings can have totally different looks and feel more integrated with their surroundings in ways that would have been impossible just a few years ago.

Curved glass has become really important in green building because it helps manage energy better and opens up new design possibilities. When buildings use this type of glass, they let in more daylight which means people don't need to turn on lights as much during the day. That cuts down on electricity costs obviously. Plus, architects love working with curved glass since it bends and shapes so well. They can create amazing exteriors that actually fit into their surroundings rather than sticking out like a sore thumb. We're seeing more interest in these kinds of environmentally friendly materials lately. Many experts think curved glass will be a standard feature in lots of construction projects going forward as cities try to meet sustainability targets without sacrificing style or function.

Recommended Products

Hot News

-

The Amazing Properties and Uses of Glass

2024-01-10

-

Production raw materials and processes of glass products

2024-01-10

-

Co-create the future! A delegation from Atlantic El Tope Hotel visited our company

2024-01-10

-

ZRGlas Shines at Sydney Build EXPO 2024, Innovative Products Spark High Interest Among Clients

2024-05-06

-

How Low-E Glass Can Cut Energy Costs and Boost Insulation

2024-09-18

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

HA

HA

LO

LO

LA

LA

MI

MI

MN

MN

TA

TA

TE

TE

MY

MY

SI

SI